How it works

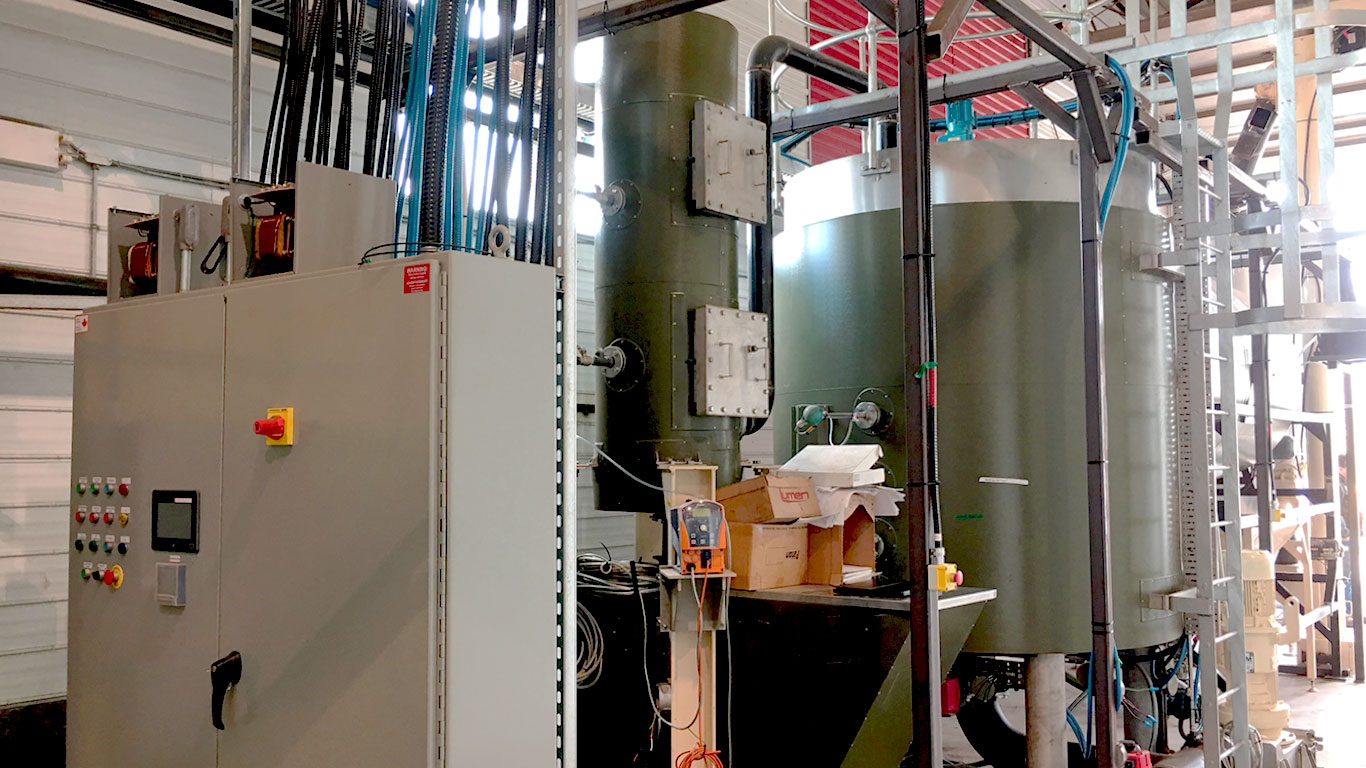

The process starts by feeding feedstock into the gasifier, which produces syngas. It goes through a two-stage clean-up process before used as a fuel for producing combine heat and power (CHP). The exhaust from the CHP is pumped into the primary aerobic digester tank and passes through a secondary aerobic digester. It is then treated in a wet-scrubber and a regenerative catalyst scrubber before being released into atmosphere.

Fuel

The gasifier process produces hydrogen and becomes fuel for the CHP. Carbon dioxide and nitrogen are also produced. Both these gases are non-combustible, and nitrogen is captured in the aerobic digester in a granular form. The CO2 emission from aerobic digester is captured as compressed liquid CO2.

Why gasification?

Solid biomass fuels are usually inefficient and can only be used for certain limited applications. The direct combustion is generally ineffectual, smokey and difficult to control. In addition, it converts solid fuel to thermal energy and whilst it is possible that heat from this process can be used in cooking, heating space and water or in generating steam (usually with low efficiency), this generation of power requires a high/medium pressure steam boiler along with a steam engine or turbine with accessories. This increases costs and difficulties for small power needs (a few kilowatts to megawatts), this conversion technology is not only capital intensive and complex, but also very inefficient. Gasification is far more efficient and cost effective.